Avondale Foods are a long-standing customer of Powertech, having completed numerous projects together spanning more than a decade. Their most recent project saw the creation of a new product line catered towards the drinks market situated within a new factory extension approximately 1000m2 in size. Powertech’s role within this project not only involved the design and installation of a refrigeration package but also project management and commissioning of the production and CIP processes.

Working collaboratively with a range of contractors from builders and mechanical installers to automation experts. Our work encapsulated the life span of the project from pre-construction design using our in-house department to coordinate MEP services with the builder right through to testing of software exclusively designed for the client to automate their process with limited operative input required.

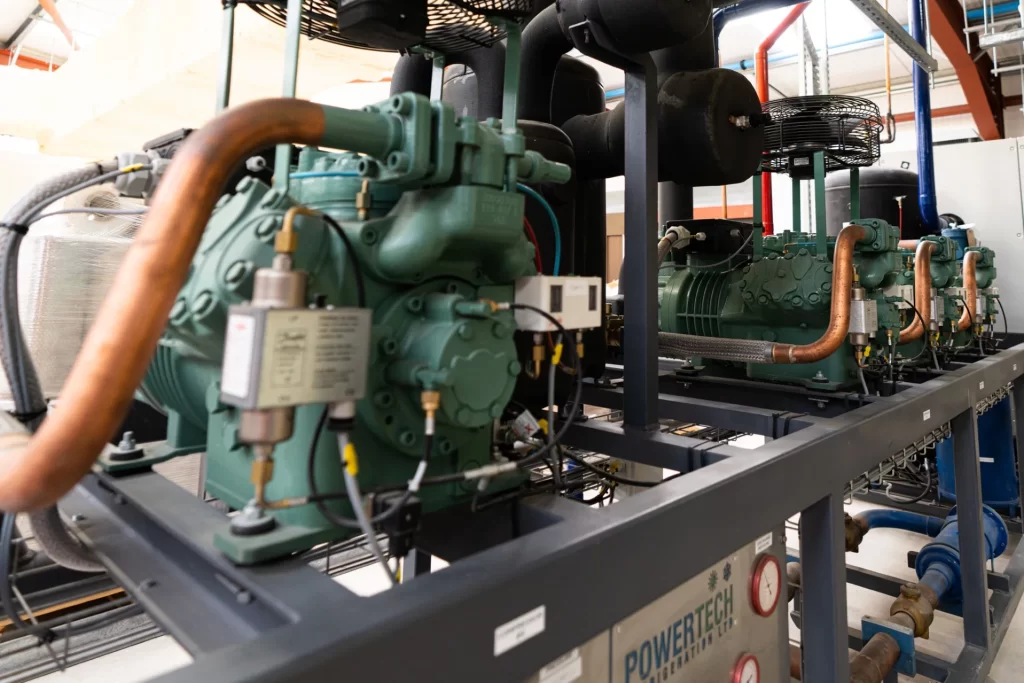

This state-of-the-art ground-breaking process, housed within a cleanroom environment constructed by Powertech using Kingspan Quadcore Insulated Panels, has enabled our client to produce vegan oat milk and coffee using a highly efficient ammonia and chilled water refrigeration system that operates without glycol to produce temperatures within a range of 1.0°C – 27.0°C. Steam sets and hot water were also integrated, operating within a temperature range of 60°C – 97°C.

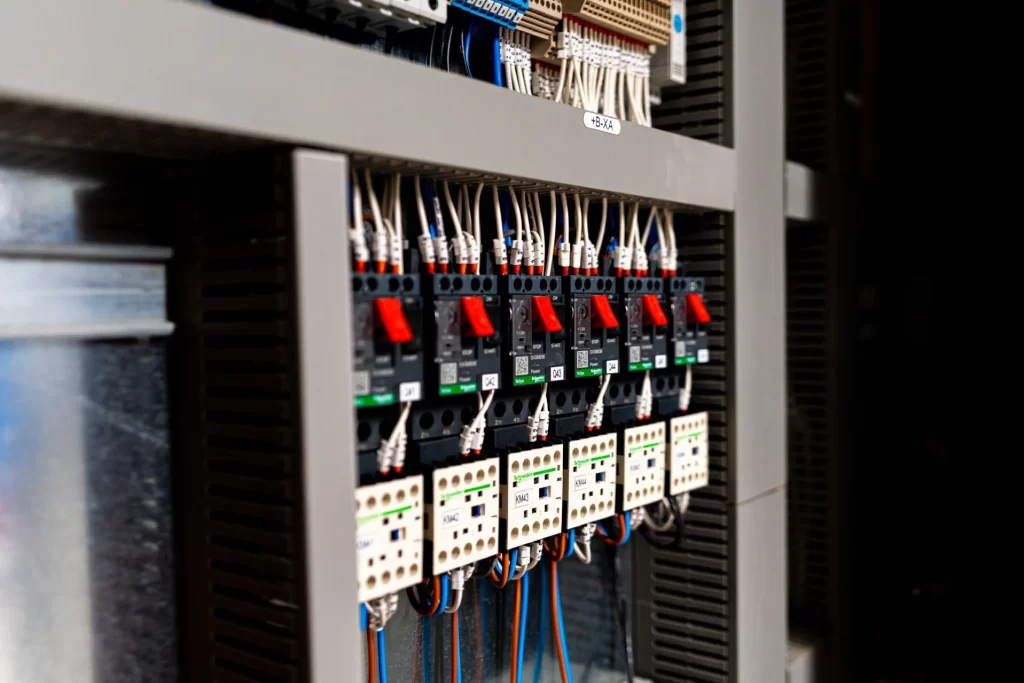

This highly complicated system required constant adjustments through each stage to get the process operating correctly and required full integration with Spectac who formulated and oversaw the installation of the process control and created a PLC system covering Low Care Production, Low Care CIP, High Care Production and High Care CIP.